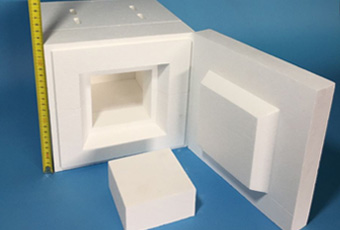

Specializing in thermal insulation lightweight fiber material

Leijing Crystal - Energy-saving butlers around you

15268289598

- Home

- About Us

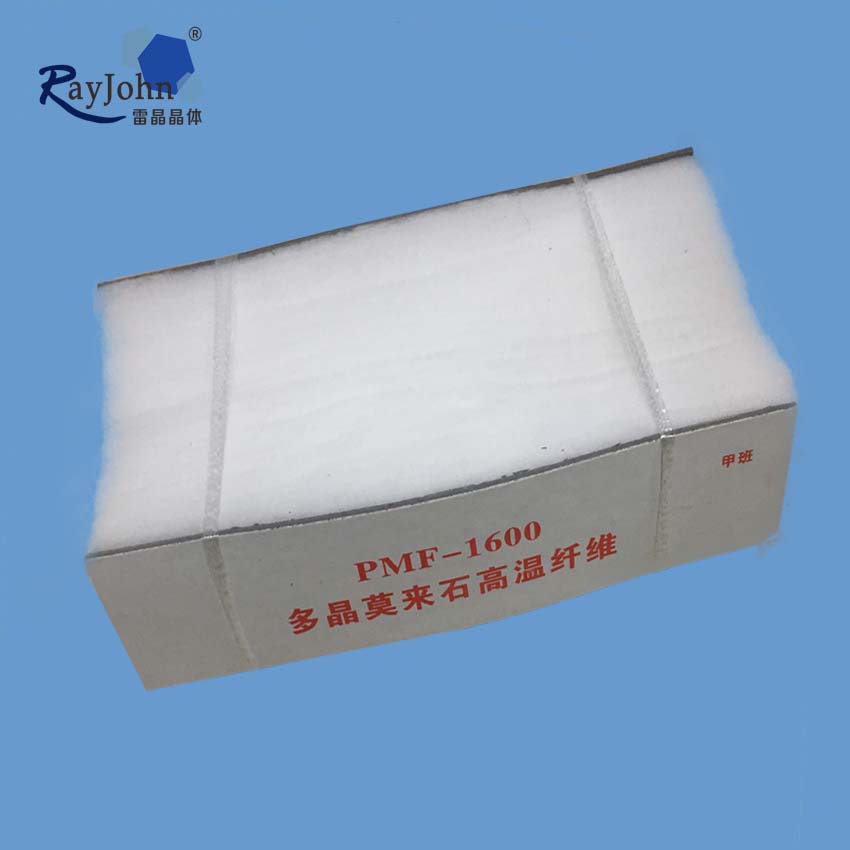

Zhejiang Deqing Leijing Crystal Fiber Co.,Ltd is an enterprise with wide application scope, large scale and high technology content.The products are developed from polycrystalline mullite fiber cotton to existing light-weight refractories that are suitable for high, medium and low temperature ranges,The application field has been extended to the fields of metallurgy, chemical industry, machinery, electronics, ceramics, building materials, scientific research and aerospace.

Zhejiang Deqing Leijing Crystal Fiber Co.,Ltd is an enterprise with wide application scope, large scale and high technology content.The products are developed from polycrystalline mullite fiber cotton to existing light-weight refractories that are suitable for high, medium and low temperature ranges,The application field has been extended to the fields of metallurgy, chemical industry, machinery, electronics, ceramics, building materials, scientific research and aerospace. - Products

- Production Capacity

Give full play to the scale management advantage of high and new technology industrialization,And committed to improving the technological progress of the kiln and promoting the development of the domestic industrial furnace to the environment-friendly and energy-saving trend that conforms to the international kilns.Strive to improve the living environment of mankind.

Give full play to the scale management advantage of high and new technology industrialization,And committed to improving the technological progress of the kiln and promoting the development of the domestic industrial furnace to the environment-friendly and energy-saving trend that conforms to the international kilns.Strive to improve the living environment of mankind. - Applications

- News

June 18-21, 2019 The company was invited to participate in the China International Ceramics Industry Exhibition for four consecutive years.

From October 30th to November 1st, 2019, the company was invited to participate in the Shanghai Fire and Refractory Exhibition for two consecutive years.

September 28-30, 2018 The company was invited to participate in the Beijing International Heat Treatment Exhibition for two consecutive years.

- Contacts

Add:No.17, Qiaomo Middle Road, Leidian Town, Deqing County, Huzhou City, Zhejiang Province

Fax:0572-8353707

Manager Gu

Tel:15268289598

Manager Lu

Tel:15805727670